Manual Transmission Components: An Overview

A manual transmission consists of key components like gears, shafts, and the clutch, working together to transfer power from the engine to the wheels efficiently.

These components are housed in a durable casing, ensuring smooth gear transitions and optimal performance.

Understanding each part’s role is essential for maintaining and repairing the system.

A manual transmission, commonly referred to as a stick shift, is a type of transmission that requires the driver to manually change gears using a clutch pedal and a gear shifter.

It is a mechanical system that transfers power from the engine to the wheels, allowing the vehicle to move efficiently under various driving conditions.

Manual transmissions are known for their simplicity, fuel efficiency, and cost-effectiveness compared to automatic transmissions.

The system relies on the driver’s ability to coordinate the clutch and gear shifter to engage and disengage gears smoothly.

This requires a basic understanding of how gears work and when to shift based on speed and acceleration.

Manual transmissions are widely used in vehicles due to their durability and performance advantages, making them a popular choice for drivers worldwide.

Key Components of a Manual Transmission

The key components of a manual transmission include the input shaft, output shaft, gears, clutch, synchronizers, and gear shifter.

The input shaft connects to the engine, while the output shaft sends power to the driveshaft.

Gears are mounted on these shafts and engage in pairs to provide different speed ratios.

The clutch is essential for disconnecting the engine from the transmission during gear shifts.

Synchronizers ensure smooth engagement of gears, preventing grinding or wear.

The gear shifter, along with shift forks, selects the desired gear.

Each component works in harmony to enable precise control over the vehicle’s speed and torque.

Understanding these parts is crucial for diagnosing issues and maintaining the transmission’s efficiency and longevity.

Gear System in Manual Transmission

The gear system enables power transfer and gear changes, consisting of input and output shafts, multiple gear sets, and synchronizers.

It ensures smooth, efficient shifting and durability.

Input Shaft and Output Shaft

The input shaft and output shaft are critical components in a manual transmission system.

They are responsible for transferring power from the engine to the transmission gears and then to the driveshaft.

The input shaft connects directly to the clutch, while the output shaft links to the driveshaft, ultimately powering the wheels.

Both shafts are precision-engineered to withstand high torque and rotational stress.

They are typically supported by bearings to ensure smooth operation and longevity.

The input shaft engages gears through the clutch, while the output shaft transmits power based on the selected gear ratio.

Together, they form the backbone of the transmission, enabling efficient power delivery and gear changes.

Gear Ratios and Their Importance

Gear ratios are a fundamental aspect of manual transmissions, determining the relationship between engine speed and wheel speed.

Different gear ratios provide varying levels of torque and speed, allowing drivers to optimize performance for specific driving conditions.

Lower gear ratios deliver more torque, ideal for acceleration and climbing steep inclines, while higher ratios prioritize speed and efficiency on highways.

The selection of appropriate gear ratios ensures smooth power delivery and optimal fuel efficiency.

Each gear ratio is carefully designed to match the vehicle’s weight, engine power, and intended use, making them crucial for overall drivetrain functionality.

Proper gear ratio configuration enhances driving experience, reduces wear on components, and maximizes vehicle performance.

Clutch System

The clutch system is essential for manually engaging and disengaging the engine from the transmission.

It allows smooth gear shifts and prevents wear on components during acceleration and deceleration.

Clutch Components and Functionality

The clutch system comprises several key components, including the clutch plate, flywheel, pressure plate, and release bearing. The clutch plate is the friction-lined disc that connects to the engine’s flywheel. When the clutch pedal is pressed, the release bearing moves to disengage the clutch plate from the flywheel, interrupting power transmission to the transmission. This allows the driver to shift gears smoothly without grinding. The pressure plate holds the clutch plate firmly against the flywheel when the pedal is released, ensuring proper engagement. Together, these components enable seamless transitions between gears, making manual transmission operation possible. Proper functioning of each part is crucial for efficient and smooth driving.

Clutch Engagement and Disengagement Process

The clutch engagement and disengagement process is fundamental to manual transmission operation. When the driver presses the clutch pedal, it activates the release bearing, which moves to disengage the clutch plate from the flywheel. This interrupts the power flow from the engine to the transmission, allowing the driver to shift gears without resistance. As the pedal is released, the spring-loaded pressure plate re-engages the clutch plate with the flywheel, restoring power transmission. Smooth and precise operation of this process is essential for seamless gear transitions and efficient driving. Improper engagement or disengagement can lead to issues like grinding gears or reduced clutch lifespan, emphasizing the importance of proper technique.

Gear Shifter and Its Components

The gear shifter is a critical component, enabling drivers to engage gears smoothly. Connected through a linkage to the transmission, it ensures precise control over gear transitions, allowing efficient vehicle operation.

Gear Shifter Mechanism

The gear shifter mechanism connects the driver to the transmission, enabling precise gear selection. It operates through a system of levers, cables, or linkages that engage and disengage gears.

The shifter’s movement is synchronized with the transmission’s internal components, such as shift forks and synchronizers, to ensure smooth transitions.

In modern vehicles, the mechanism often includes a manual or cable-actuated system, providing a direct feel for the driver.

The gear shifter’s design varies, with some incorporating electronic assists for enhanced control.

Its role is crucial for efficient power delivery and vehicle performance.

Shift Fork and Synchronizers

Shift forks and synchronizers are critical components within a manual transmission, ensuring smooth and precise gear changes.

The shift fork moves along the transmission shaft, engaging gears by pushing them into place.

Synchronizers, equipped with cone-shaped clutch rings, synchronize the rotation of gears with the shaft before engagement.

This mechanism prevents grinding and damage during shifts.

The shift fork’s movement is guided by the gear shifter, while synchronizers reduce wear by aligning gear speeds.

Together, they maintain transmission efficiency and extend component lifespan.

Types of Gear Shifters

Manual transmissions feature various gear shifter types, each designed for specific driving needs.

The most common is the floor-mounted shifter, typically located between the front seats.

Column-mounted shifters are found in older vehicles, integrated into the steering column.

Sequential shifters, often used in performance cars, require moving the lever in a fixed pattern.

Automated manual shifters combine manual control with automatic clutch operation.

Each design aims to enhance driver control and shifting precision, catering to different preferences and driving conditions.

Transmission Housing and Mounts

The transmission housing is made of durable materials like aluminum or steel to protect internal components.

It is designed to withstand stress and ensure smooth operation.

Mounts secure the housing to the chassis, reducing vibration and noise.

They are typically made of rubber or hydraulic mounts for optimal stability.

Transmission Housing Materials and Design

Transmission housings are crafted from robust materials such as aluminum, steel, or magnesium to ensure durability and strength.

These materials are chosen for their ability to withstand the mechanical stresses of gear operation and torque transfer.

The design typically features a rigid structure with internal partitions to compartmentalize gears and bearings, enhancing structural integrity.

Some high-performance transmissions may incorporate lightweight materials to reduce overall weight without compromising strength.

The housing is often ribbed or reinforced to minimize flex and vibration, ensuring smooth power delivery.

Additionally, the design includes mounting points for secure attachment to the vehicle’s chassis, helping to isolate noise and vibration.

Modern manufacturing techniques, such as casting or machining, are employed to achieve precise tolerances and a reliable seal.

This ensures optimal performance and longevity of the transmission system.

Role of Transmission Mounts

Transmission mounts play a crucial role in securing the manual transmission to the vehicle’s chassis, ensuring stability and proper alignment.

These mounts are typically made of durable materials like rubber or hydraulic bushings, designed to absorb vibrations and shocks from the transmission.

By isolating the transmission, they prevent unwanted vibrations from being transferred to the driver, enhancing ride comfort.

Transmission mounts also contribute to maintaining proper drivetrain alignment, which is essential for efficient power delivery and gear operation.

Over time, worn-out mounts can lead to increased noise, vibration, and potential damage to the transmission and surrounding components.

Regular inspection and replacement of transmission mounts are vital to maintain the overall performance and longevity of the vehicle’s drivetrain system.

Transmission Fluid

Transmission fluid is essential for lubricating gears, cooling components, and enabling smooth gear shifts in manual transmissions.

It prevents overheating and wear, ensuring optimal performance and longevity.

Regular fluid checks and changes are crucial for maintaining transmission health.

Importance of Transmission Fluid

Transmission fluid plays a critical role in maintaining the health and functionality of a manual transmission system. It acts as a lubricant, reducing friction between moving components like gears and shafts, which prevents overheating and wear. Additionally, transmission fluid serves as a coolant, dissipating heat generated by the constant engagement and disengagement of gears during operation. This helps to extend the lifespan of the transmission by maintaining optimal operating temperatures. Without proper lubrication, the system would experience increased friction, leading to premature wear and potential failure. Regular monitoring and replacement of transmission fluid are essential to ensure smooth gear transitions and overall system efficiency.

Types of Transmission Fluids

Manual transmissions utilize specific types of transmission fluids to ensure optimal performance and longevity. Common types include conventional transmission fluid, synthetic transmission fluid, and synthetic blend; Conventional fluid is suitable for most standard vehicles, offering reliable lubrication and heat resistance. Synthetic fluid, on the other hand, provides superior performance in extreme temperatures and under heavy loads. Synthetic blend combines the benefits of both, offering enhanced durability at a lower cost than full synthetic. Some vehicles may require specialized fluids, such as high-mileage or heavy-duty formulations. Always consult the vehicle’s manual to select the correct type, as using the wrong fluid can lead to reduced performance or damage to the transmission system.

Driveshaft and Differential

The driveshaft connects the transmission to the differential, transmitting power to the wheels. The differential allows wheels to rotate at different speeds, essential for smooth turning and traction.

Driveshaft Function in Manual Transmission

The driveshaft plays a critical role in manual transmission systems by transferring torque from the transmission to the differential. It is a long, cylindrical component designed to rotate at high speeds, ensuring power is delivered to the wheels efficiently. The driveshaft is connected to the output shaft of the transmission and the input shaft of the differential, enabling smooth power transition. During acceleration, the driveshaft spins, transmitting engine power through the transmission and differential to the wheels. Its balanced design minimizes vibrations, ensuring a smooth driving experience. Proper alignment and maintenance of the driveshaft are essential to avoid damage and ensure optimal performance of the manual transmission system.

Differential and Its Role

The differential is a critical component in manual transmission systems, located between the rear wheels. Its primary function is to split power from the driveshaft to the wheels while enabling them to rotate at different speeds during cornering. This ensures smooth, efficient traction and prevents wheel skidding. The differential consists of a ring gear, pinion gear, and spider gears, which work together to distribute torque effectively. It plays a vital role in maintaining stability and control, especially during sharp turns. Proper functioning of the differential ensures optimal power delivery and enhances overall vehicle performance. Regular maintenance is essential to prevent wear and tear, ensuring the differential operates smoothly and efficiently under various driving conditions.

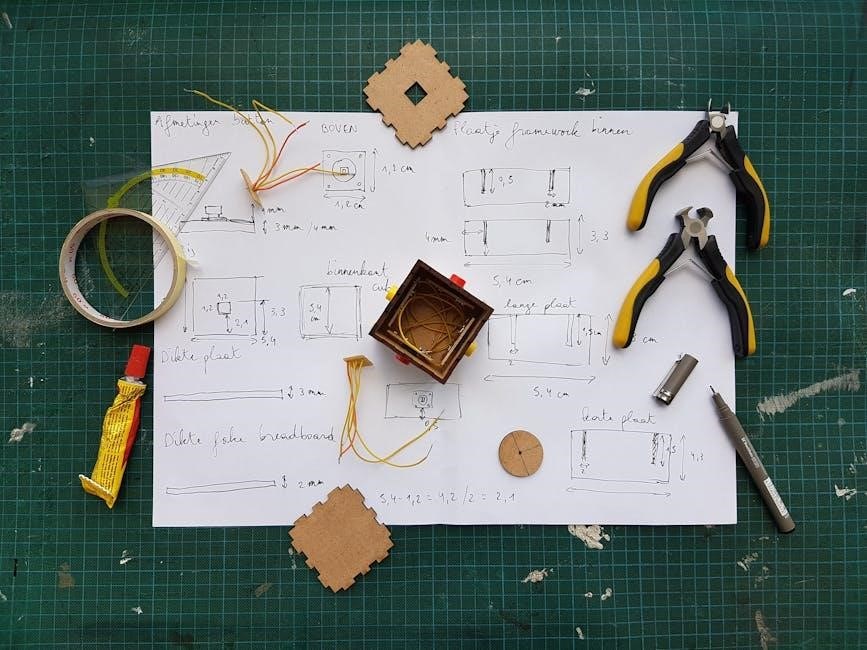

Manual Transmission Identification

Manual transmissions can often be identified by their shape, gear count, and specific markings. This identification is crucial for maintenance, diagnostics, and compatibility with vehicle systems.

Identifying Manual Transmission Types

Identifying manual transmission types involves examining physical characteristics, such as the shape of the transmission casing and gear count.

Some transmissions have unique markings or engravings on the housing, indicating the model or manufacturer.

Additionally, the location of the serial number, often found on the rear or side of the casing, can help determine the specific type.

Consulting the vehicle’s service manual or contacting the manufacturer with the serial number provides precise identification.

Different models may have distinct features, such as the number of gears or the design of the shifter mechanism.

Understanding these details is crucial for maintenance, repairs, and ensuring compatibility with other vehicle components.

Transmission Model Identification

Transmission model identification can be achieved by locating the serial number on the casing and referencing the manufacturer’s database.

Visual inspection of the transmission’s shape, particularly the oil pan, often reveals unique features specific to certain models.

Additionally, gear count and shifter mechanism design can help differentiate models.

Consulting service manuals or manufacturer websites with the serial number provides precise identification.

This process is essential for maintenance, repairs, and ensuring compatibility with other vehicle components.

Maintenance and Troubleshooting

Regular inspection of transmission fluid, gear wear, and clutch condition is crucial for optimal performance and longevity of the manual transmission system.

Common Issues in Manual Transmissions

Common issues in manual transmissions include grinding gears, difficulty shifting, and clutch problems. These issues often arise from worn-out components like synchronizers or bearings.

Low transmission fluid levels or contamination can also cause malfunction. Symptoms may include unusual noises, vibrations, or resistance when changing gears.

Addressing these problems early prevents further damage and ensures smooth operation. Regular maintenance, such as fluid checks and inspections, is essential to avoid costly repairs.

Diagnostic Techniques for Manual Transmissions

Diagnosing manual transmission issues involves a combination of visual inspections, listening for unusual noises, and physical checks. Start by inspecting the transmission fluid level and condition, as low or dirty fluid can cause poor performance.

Next, listen for grinding, whining, or clunking sounds during gear shifts, which may indicate worn gears or bearings.

Visually inspect the clutch and gear components for wear or damage.

Also, check for any signs of leaks or corrosion on the transmission housing.

Finally, test drive the vehicle to identify issues like difficulty shifting or slipping gears.

These steps help pinpoint common problems like faulty synchronizers or a failing clutch. Early detection is key to preventing further damage and ensuring reliable operation.

Understanding manual transmission components is crucial for drivers, enabling better maintenance, troubleshooting, and overall vehicle performance. This knowledge enhances driving efficiency and longevity of the transmission system.

Importance of Understanding Manual Transmission Components

Understanding manual transmission components is vital for drivers and mechanics to ensure optimal performance and longevity.

Knowledge of gears, shafts, and clutch systems enables better maintenance and troubleshooting.

It helps identify common issues like worn-out synchronizers or low transmission fluid early, preventing costly repairs.

Moreover, it empowers drivers to handle repairs and adjustments confidently.

This understanding also enhances driving efficiency, as proper gear shifting and clutch engagement can improve fuel economy and reduce wear.

Familiarity with components like the gear shifter, shift forks, and differential aids in diagnosing problems accurately.

Ultimately, comprehension of manual transmission parts is key to extending the system’s lifespan and ensuring smooth operation.