GE Refrigerator Repair Manual: An Overview

Access comprehensive GE refrigerator repair manuals as PDF downloads, offering vital information like parts lists and wiring diagrams for effective troubleshooting and diagnostics.

OEM service manuals are available in booklet format, assisting with accurate problem diagnosis and providing repair advice to restore your refrigerator’s functionality.

Understanding GE Refrigerator Service Manuals

GE refrigerator service manuals are essential resources for both seasoned technicians and DIY enthusiasts tackling appliance repairs. These manuals, often available as PDF downloads or in booklet format, provide a detailed roadmap for understanding the intricate workings of your refrigerator.

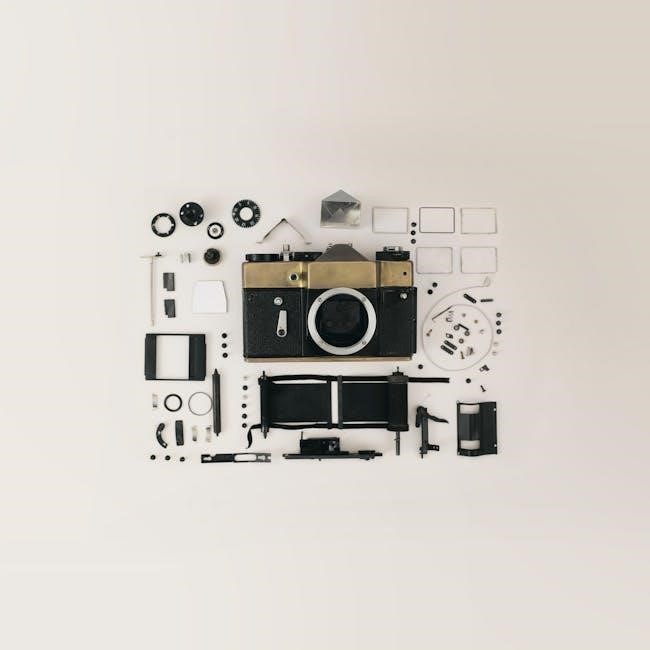

They typically include exploded diagrams illustrating component placement, aiding in disassembly and reassembly. Crucially, they feature diagnostic charts to pinpoint the source of malfunctions, alongside comprehensive component testing procedures. Wiring diagrams are also included, vital for electrical troubleshooting.

Furthermore, these manuals decode error codes displayed by modern GE refrigerators, translating cryptic signals into actionable repair steps. Accessing the original equipment manufacturer (OEM) manual ensures you’re working with accurate, refrigerator-specific information, maximizing your chances of a successful repair and avoiding potential safety hazards.

Accessing GE Refrigerator Repair PDFs

Obtaining a GE refrigerator repair PDF manual is now remarkably straightforward. Numerous online platforms specialize in providing appliance service manuals, offering instant digital access. A quick web search for “GE refrigerator service manual PDF” will yield a variety of options, often requiring a small download fee.

Ensure the source is reputable to guarantee the manual’s accuracy and completeness. Some websites offer subscriptions granting access to a vast library of manuals, while others sell individual manuals on demand.

Downloading the PDF allows immediate access to crucial repair information, including parts lists, disassembly instructions, and diagnostic procedures. You can then easily print specific sections or view them directly on a tablet or laptop during the repair process, offering convenience and efficiency.

Common GE Refrigerator Problems & Troubleshooting

Diagnose issues like inadequate cooling, food spoilage, leaks, and noises with our guide, providing accurate problem identification and repair advice for your GE fridge.

Inadequate Cooling: Initial Checks

Begin troubleshooting inadequate cooling by verifying the thermostat settings, ensuring they are appropriately adjusted for desired temperatures within both the refrigerator and freezer compartments.

Next, meticulously check for proper airflow around the vents; obstructions like overpacked items can significantly impede circulation. Confirm that vents aren’t blocked by food containers or ice buildup.

Crucially, inspect and clean the condenser coils, as dust and debris accumulation drastically reduces cooling efficiency. Dirty coils force the compressor to work harder, diminishing performance. Regular cleaning is essential.

Finally, ensure the door seals are intact and creating a tight closure; compromised seals allow warm air to enter, impacting cooling. Test by closing the door on a piece of paper – resistance indicates a good seal.

Persistent Food Spoilage: Causes and Solutions

Persistent food spoilage often indicates temperature fluctuations or insufficient cooling. First, verify the refrigerator’s temperature using a thermometer, ensuring it remains consistently below 40°F (4°C).

Investigate the door seals for proper closure; leaks allow warm air to enter, accelerating spoilage. Check for condenser coil cleanliness, as dirty coils reduce cooling capacity. Ensure adequate airflow around food items.

Consider the possibility of a malfunctioning defrost system. If ice builds up excessively, it hinders cooling and can lead to temperature inconsistencies. Examine the defrost heater, timer, and thermostat.

Finally, avoid overcrowding the refrigerator, as this restricts airflow. Proper food storage practices, like sealing leftovers, are also vital to minimize spoilage and maintain freshness.

Unusual Leaks: Identifying the Source

Unusual leaks within a GE refrigerator can stem from several areas, requiring careful investigation. Begin by checking the water dispenser line and connections for any visible cracks or looseness.

Inspect the defrost drain, located at the back of the freezer, for clogs that may cause water to overflow. Examine the drain pan beneath the refrigerator; a cracked or improperly positioned pan can lead to leaks.

If the leak originates inside the refrigerator, assess the humidity control system and ensure proper sealing around the doors. Check for condensation buildup, which could indicate a temperature issue.

For ice maker leaks, verify the water supply line and ice maker components. Remember to disconnect power before inspecting any electrical components related to the water system.

Bothersome Noises: Diagnosing the Sound

Identifying the source of bothersome noises in your GE refrigerator is crucial for effective repair. A rattling sound often points to a loose condenser fan blade or an improperly secured component at the back.

Buzzing noises could indicate a failing compressor or a problem with the defrost timer. Clicking sounds might originate from the defrost heater relay or the ice maker’s solenoid valve.

Humming sounds are frequently associated with the condenser fan motor or the compressor itself. If you hear a high-pitched squealing, it could be a worn evaporator fan motor bearing.

Carefully listen to pinpoint the location of the noise and use a GE refrigerator repair manual to identify the corresponding component. Always disconnect power before inspecting internal parts.

Key Components & Repair Focus

Focus on vital components like the thermostat, condenser coils, evaporator fan motor, and defrost system for successful GE refrigerator repairs and optimal performance.

Thermostat Functionality & Adjustment

The thermostat is crucial for maintaining the correct temperature within your GE refrigerator; it acts as the control center, signaling the compressor when to cycle on and off. Initial troubleshooting for cooling issues should always begin with verifying the thermostat’s settings – ensure it isn’t accidentally set too warm or to an ‘off’ position.

Proper airflow around the thermostat is also essential for accurate readings. Obstructions can lead to inaccurate temperature sensing. Adjustment typically involves a dial or digital controls, allowing you to select the desired cooling level. If the thermostat appears faulty – unresponsive or providing inconsistent readings – testing with a multimeter is recommended.

Replacement may be necessary if the thermostat fails to regulate temperature effectively. Always consult the refrigerator’s service manual for specific testing procedures and part numbers to ensure compatibility and a successful repair.

Condenser Coils: Cleaning & Maintenance

Condenser coils dissipate heat, and maintaining their cleanliness is vital for efficient refrigerator operation. Dust and debris accumulation significantly reduces cooling performance, forcing the compressor to work harder and potentially leading to failure. Regular cleaning – ideally every six months – is a preventative measure that extends the refrigerator’s lifespan.

Locate the coils, typically on the back or bottom of the unit. Disconnect power before cleaning! Use a vacuum cleaner with a brush attachment to gently remove dust. For stubborn grime, a condenser coil cleaning brush can be employed. Avoid bending the fins, as this restricts airflow.

Improved cooling efficiency is the immediate benefit of clean coils. Consistent maintenance prevents overheating and ensures optimal performance, saving energy and reducing repair costs. Refer to your GE refrigerator’s manual for specific cleaning recommendations.

Evaporator Fan Motor: Testing & Replacement

The evaporator fan motor circulates cold air throughout the refrigerator and freezer compartments. A malfunctioning motor results in inadequate cooling or frost buildup. Testing involves visually inspecting the fan blade for obstructions and then using a multimeter to check for continuity. Disconnect power before any testing!

If the motor lacks continuity, it requires replacement. Access typically involves removing shelves and panels within the freezer. Document wire connections before disconnecting them. Install the new motor, ensuring proper alignment and secure mounting. Reconnect the wiring, and restore power.

Listen for the fan to operate. If it doesn’t, double-check connections. A faulty motor can cause significant temperature fluctuations, impacting food preservation. Consult your GE refrigerator’s service manual for model-specific instructions and safety precautions during this repair.

Defrost System: Heater, Timer & Thermostat

The defrost system prevents ice buildup on the evaporator coils. It comprises a heater to melt frost, a timer to initiate defrost cycles, and a thermostat to regulate temperature. A faulty system leads to excessive frost, reduced cooling, and potential compressor damage.

Testing the heater involves checking for continuity with a multimeter (disconnect power first!). The timer’s operation can be observed during a defrost cycle. The defrost thermostat should show continuity when cold. Replacement requires accessing the evaporator compartment.

Carefully disconnect and reconnect wiring, noting the original configuration. A malfunctioning defrost thermostat can prevent the heater from activating. Always refer to your GE refrigerator’s service manual for specific component locations and testing procedures. Proper defrost function is crucial for optimal performance.

Advanced Troubleshooting & Diagnostics

Decode error codes for precise fault identification, utilize wiring diagrams for component tracing, and perform thorough component testing to pinpoint complex GE refrigerator issues.

Wiring Diagrams: Interpretation & Use

Understanding GE refrigerator wiring diagrams is crucial for effective troubleshooting and repair. These diagrams visually represent the electrical connections within the appliance, detailing the pathways for power and signals to various components. Key elements include symbols for components like relays, switches, motors, and thermostats, alongside wire colors and numbers for identification.

When interpreting a diagram, start by identifying the power source and tracing the circuits to the faulty component. Pay close attention to grounding connections and safety features. Use a multimeter to verify continuity and voltage levels, comparing readings to the diagram’s specifications. Proper diagram usage minimizes guesswork, prevents electrical hazards, and ensures accurate repairs. Always disconnect power before working with wiring!

Remember to consult the specific diagram for your refrigerator model, as variations exist. Diagrams are often included within the service manual PDF downloads.

Error Codes: Decoding GE Refrigerator Signals

GE refrigerators utilize error codes to signal malfunctions, streamlining the diagnostic process. These codes, displayed on the control panel or accessed through diagnostic modes, pinpoint specific component failures or system issues. Decoding these signals requires referencing the refrigerator’s service manual, as code meanings vary by model.

Common codes might indicate problems with the evaporator fan motor, defrost heater, temperature sensors, or control board. For example, a code related to the defrost system could suggest a faulty heater, timer, or thermostat. Accurate interpretation prevents unnecessary part replacements and ensures targeted repairs.

Service manuals provide comprehensive lists of error codes and their corresponding solutions. Utilizing these resources, alongside component testing, allows technicians to efficiently diagnose and resolve refrigerator problems. Remember to always record the error code before attempting any repairs.

Component Testing Procedures

Effective refrigerator repair hinges on accurate component testing. Service manuals detail specific procedures for evaluating parts like the thermostat, defrost heater, and evaporator fan motor. Multimeters are essential for checking continuity, resistance, and voltage, verifying electrical functionality.

Testing the thermostat involves confirming it opens and closes at the correct temperatures. Defrost heaters require checking for continuity to ensure they aren’t open-circuited. Evaporator fan motors should be tested for proper rotation and voltage supply.

Always disconnect power before testing electrical components. Refer to wiring diagrams to identify correct test points. Carefully follow the manual’s instructions to avoid damaging components or creating safety hazards. Proper testing isolates faulty parts, minimizing unnecessary replacements.

Specific GE Refrigerator Models & Manuals

GE refrigerator repair varies by model; top freezer, bottom freezer, and side-by-side units present unique challenges requiring specific service manuals for accurate diagnosis and repair.

Top Freezer Models: Repair Considerations

Top freezer GE refrigerators, while often simpler in design, require focused troubleshooting when issues arise. Common repairs frequently involve the defrost system – heater, timer, and thermostat – as frost buildup can impede cooling. Component testing is crucial to pinpoint failures within this system.

Thermostat functionality should be verified, ensuring accurate temperature regulation. Condenser coil cleaning is essential for efficient heat dissipation, directly impacting cooling performance. Evaporator fan motor issues can also cause temperature fluctuations or complete cooling loss, necessitating testing and potential replacement.

Wiring diagrams specific to the model are invaluable for tracing electrical faults. Error codes, if displayed, provide direct clues to the problem area. Remember to always disconnect power before undertaking any repair work and consult the appropriate service manual for detailed instructions and safety precautions.

Bottom Freezer Models: Unique Challenges

Bottom freezer GE refrigerators present distinct repair challenges due to their complex design and component placement. Troubleshooting often centers around the evaporator fan motor located within the freezer compartment, impacting both freezer and refrigerator temperatures. Defrost system failures are also common, requiring careful inspection of the heater, timer, and thermostat.

Airflow optimization is critical in these models; blocked vents can lead to uneven cooling. Component testing procedures, detailed in the service manual, are essential for accurate diagnosis. Wiring diagrams become particularly important given the increased electrical complexity.

Unique challenges include accessing components located behind panels and drawers. Always consult the specific model’s service manual for disassembly instructions. Prioritize safety by disconnecting power before any repair attempt and carefully following the outlined procedures.

Side-by-Side Models: Common Issues

GE side-by-side refrigerators frequently experience issues with their ice and water dispensers, often stemming from frozen water lines or faulty inlet valves. Evaporator fan motor failures are also prevalent, leading to temperature inconsistencies in both the freezer and refrigerator sections. Defrost system malfunctions, including heater and thermostat problems, are common causes of ice buildup.

Troubleshooting these models requires careful attention to the dual cooling systems. Wiring diagrams are crucial for navigating the complex electrical components. Component testing, as outlined in the service manual, is vital for accurate diagnosis.

Persistent food spoilage can indicate a failing door seal or a malfunctioning temperature control board. Always refer to the specific model’s manual for detailed repair instructions and safety precautions.

Preventative Maintenance for GE Refrigerators

Optimize airflow by cleaning vents and regularly cleaning condenser coils to maintain cooling efficiency; replace water filters according to guidelines for peak performance.

Airflow Optimization & Vent Cleaning

Maintaining proper airflow is crucial for consistent cooling throughout your GE refrigerator. Blocked vents restrict cold air circulation, leading to temperature inconsistencies and potential food spoilage. Regularly inspect the vents located in the freezer and refrigerator compartments, ensuring they aren’t obstructed by food items.

Remove any items blocking the vents and clean them with a soft cloth and mild detergent. Pay attention to the return vents, often found near the top of the refrigerator, as these are particularly prone to dust accumulation. Dust and debris significantly impede airflow, forcing the compressor to work harder and reducing efficiency.

Consider rearranging items within the refrigerator to allow for better air circulation. Avoid overcrowding shelves, and leave space between items to facilitate airflow. Consistent vent cleaning and airflow optimization are simple yet effective preventative measures that can significantly extend the life of your GE refrigerator and ensure optimal performance.

Regular Coil Cleaning Schedule

Condenser coils dissipate heat, and a buildup of dust and debris drastically reduces their efficiency. Establishing a regular cleaning schedule is vital for maintaining optimal refrigerator performance. Ideally, coils should be cleaned at least twice a year, or more frequently if you have pets or live in a dusty environment.

Before cleaning, disconnect the refrigerator from the power source. Locate the condenser coils – typically found on the back or bottom of the unit. Use a vacuum cleaner with a brush attachment to gently remove loose dust and debris. For stubborn buildup, a specialized coil cleaning brush can be used.

Avoid using harsh chemicals or abrasive cleaners, as these can damage the coils. Consistent coil cleaning reduces energy consumption, extends the lifespan of the compressor, and ensures your GE refrigerator operates at peak efficiency, preventing potential repair needs.

Water Filter Replacement Guidelines

Maintaining a fresh water filter is crucial for delivering clean, great-tasting water and ice. GE recommends replacing the water filter every six months, or sooner if you notice a decrease in water flow or a change in taste. Ignoring this can lead to reduced water quality and potential issues with the ice maker.

To replace the filter, first locate it – typically inside the refrigerator compartment or in the base grille. Turn off the water supply to the refrigerator. Gently twist or push the old filter to release it, following the instructions specific to your GE model. Install the new filter, ensuring it’s securely in place.

After installation, flush the system by dispensing several gallons of water to remove any air or loose particles. Regular filter replacement safeguards your family’s health and preserves the longevity of your refrigerator’s water dispensing system.